A floating ball valve is a valve with its ball

floating (not fixed by a trunnion) inside the valve body, it drifts

toward to the downstream side and tightly pushes against the seat under

the medium pressure to ensure sealing reliability. The floating ball

valve has simple structure, good sealing performance but the seat

material is required to withstand the workload since the sealing

pressure is bared by the seat ring. Due to unavailability of high

performance seat material, floating ball valve is mainly used in middle

or low pressure application.

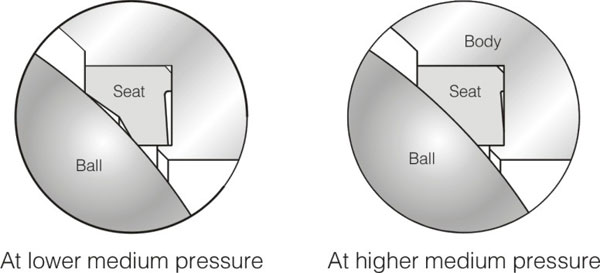

Design FeaturesReliable Seat Seal

The structure design of double-beveled

sealing ring has been adopted to reduce the friction between the ball

and the sealing ring to achieve lower operation torque. When

the medium pressure is low, the ball has smaller contacting surface

with sealing ring, which introduces higher sealing pressure to ensure

the sealing reliability. When the medium pressure gets higher, the

contacting area between ball and sealing ring increases accordingly.

Larger contact area reduces the sealing pressure to avoid the

deformation of sealing ring.

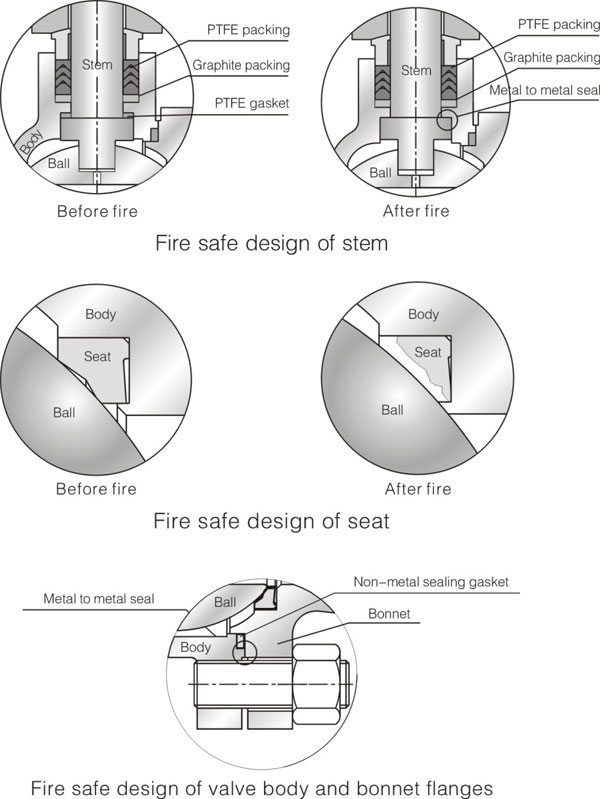

Fire Safe Design

In case of fire, non-fireproof material for

packing and seat will be burnt-out and considerable medium leakage may

possibly cause fire spread. CRV adopted metal to metal seal as

auxiliary structure to prevent medium leakage in case of fire as shown

in figures. The fire safe design confirms to the requirements of

API607, API 6FA and BS 6755.